Why the rotating field is better than rotating armature?

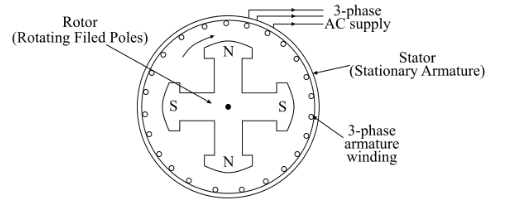

A stationary armature-rotating field alternator has several advantages over a rotating armature-type alternator, as given below-

When a stationary armature is used in the alternator, the output current can be taken directly from the fixed terminals on the stationary armature without using slip rings, brushes, etc.

- The armature windings of the rotating field alternator, being stationary, are not subjected to vibration and centrifugal forces.

- A stationary armature can be easily insulated for the high voltage for which the alternator is designed. This generated voltage may be as high as 33 kV.

- When the stationary armature is used, the armature windings can be braced better mechanically against the high electromagnetic forces due to large short circuit currents.

- The rotating field is supplied with the direct current. Thus, only two slip rings are required to provide direct current for the rotating field. Generally, the field voltage is between 100 to 500 volts and hence the insulation of the low-voltage slip rings from the shaft can be provided easily.

- The weight of the armature windings is greater than the windings of the rotating field poles. Therefore, the rotating field type alternator has a smaller size than a rotating armature type alternator.

- a stationary armature may be cooled easily because the size of the armature can be increased to provide more cooling ducts.

- Since the rotating field is comparatively light, it can be constructed for high-speed rotation.

- The forced cooling with gas or liquids can be easily provided in stationary armature-type alternators.

- The cost of the rotating field type alternator is low as compared to the rotating armature type alternator.